Products & Services:

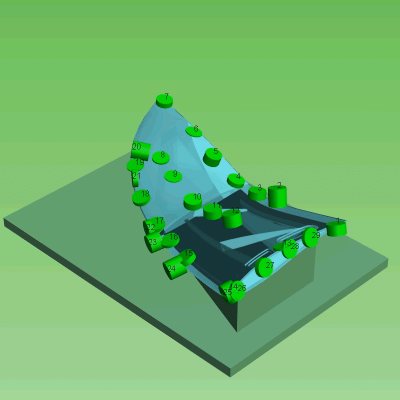

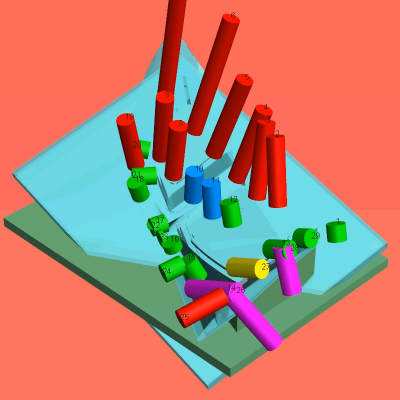

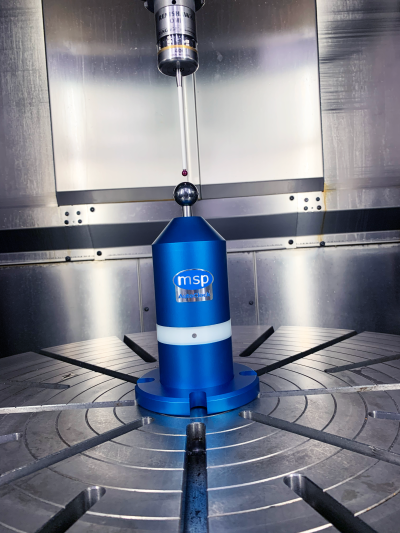

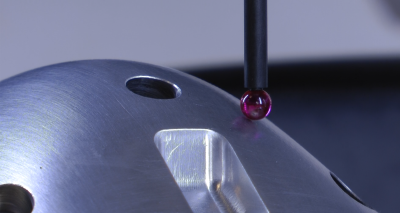

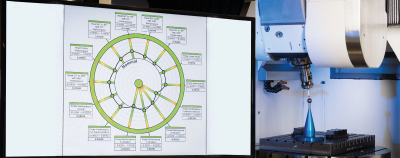

MSP provides world-class metrology solutions for the CNC manufacturing industry worldwide. Its MSP PerfectPart product suite removes all errors from CNC machining processes to ensure for an accurate and sustainable end-to-end operation producing right-first-time parts. AutoClock gives automated and accurate probe setup and calibration, NC-Checker ensures accurate machine tool performance and capability, and NC-PartLocator delivers automated and accurate part alignment and on-machine inspection. All products work automatically and make it possible to achieve 24/7 lights-out automation.

Quality Approvals:

ISO 9001: 2015; JOSCAR: SafeContractor

Market Experience:

Our client portfolio includes blue chip manufacturers across multiple industries, aerospace (defence and civilian), space, additive, energy, and motorsport, some of which have experienced significant results: complex part setup reduced from 7 days to 4 hours, 157% increases in machine capacity and 100% increases in productivity.

Key Equipment and Processes

AutoClock hardware device for touch probe setup and calibration. NC-Checker software (loaded onto a PC connected to the machine tool controller) to provide statistics about the machine tool’s performance and correct specific errors. NC-PartLocator software (loaded onto a PC connected to the machine tool controller) which calculates the correct alignment for the part and uploads it automatically to the controller. This same software also makes it possible to perform on-machine inspection.

Major Customers

Renishaw, Spirit Aerospace, Leonardo, Orbex, Safran, Quickstep, Pratt & Whitney, leading F1 teams, and others.